Peening pins in a knife handle can be pretty straight forward depending on the pin material. Brass and aluminum are soft, and they’re easier to peen when compared to stainless. The next step would be to trim the pins at about 1/16 inches to fit the scales.

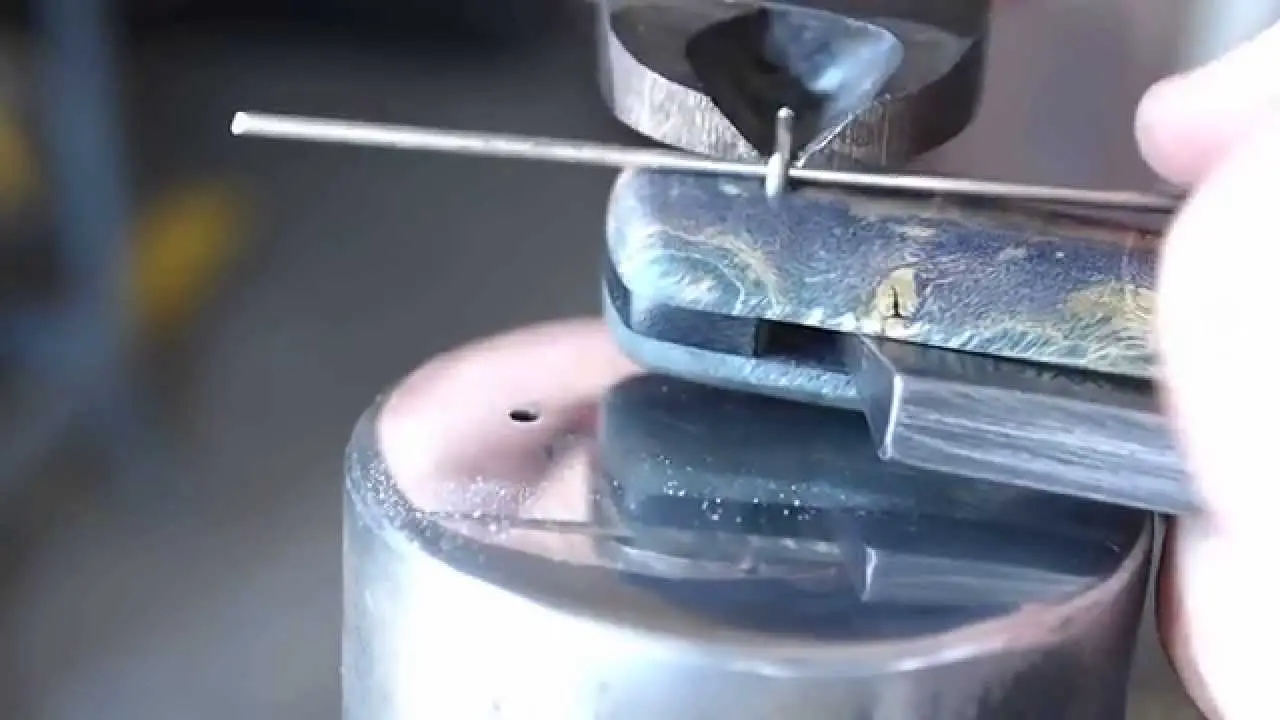

Using a ball peen hammer, gently tap each pin while the other end remains flat on a steel surface. Once the pin end starts to spread, turn the knife over and repeat the process with the other pin end.

That’s pretty much the basics on how to peen pins in a knife handle. Nonetheless, there’s a certain technique needed to guarantee each one of the pins remains in place.

In this article, I’ll explain what tools are necessary for peening knife handle pins and how to use them during every step. This way, pins will stick to the handle scales and the knife’s tang for a longer time.

Why Should You Peen Pins in Knives?

Properly peened pins form a mechanical bond between the scale and handle of a kitchen knife. In other words, the peening process keeps knives and handles together to avoid displacement.

Unlike using glue that’d eventually fall off, the peening process has been a reliable method to create knives for decades.

In the next section, I’ll explain the DIYer’s method for peening knife handle pins.

How to Peen Pins in Wooden Knife Handle: 4 Simple Steps

The peening process is relatively easy. It only consists of four easy steps, which anyone can do at home.

Grab These Essentials

- Epoxy. Glue is a part of the peening process to keep the two pieces of the handle scale attached to metal tangs via peened pins. Using Epoxy will also reduce fatigue properties and shallow surface cracks. Plus, water or air pressure won’t get between the handle and metal material after peening.

- A metal tapered reamer. While peening, this tool will help each pin to get a good fit into the pin hole.

- A ball-peen hammer. A two or three-ounce peening hammer should do. For peening pins, the hammer is not about mass but shot velocity.

- Pin punch. To tap the pins back out after applying the Epoxy.

- Small nylon brush. This item is perfect for cleaning the holes and polish the metal surface before peening.

- A strong metal surface. Anvil on a bench vice, a steel plate, or other sites equally durable will do. You’ll need a metal surface for support during peening.

- An angle grinder plus a belt sander to trim the pins if necessary; you can trim the pins before the peening process or after it.

Step 1: Epoxy the Knife

Epoxy helps glue the knife’s metal tang with the handle during this step of the peening process. It’s a basic method for knives, unlike soldered or welded joints. By doing this, you’ll also avoid having loose scales and the process to peen the pins will go smoothly.

Adding glue is a great idea because it gives the handle material support before using the hammer to get the peened pins aligned. It also sticks to metal materials properly—each shot taken on the pins while peening won’t move or displace the scales.

Before peening, add Epoxy as needed with the pins in place. Give the Epoxy enough exposure time until it cures. Then, use the pin punch to get the pins out with light taps.

Step 2: Use Tapered Reamer to Make a See-Through Hole

With the handle scales attached to the tang and after the Epoxy sets, use the tapered reamer to create see-through holes with a clean surface layer.

This is a basic method of the peening techniques that can leave surface roughness on the material afterward. Once you are done, you can polish these impurities to get clean tang holes.

Use the nylon brush to remove the dirt over the scales surfaces and from inside. This will leave every surface clean to fit the pins properly once you start peening.

Can I use a countersink for peening pins?

Countersink can create see-through holes in the scale material surface. However, this tool will create a hole too large for the pins to fit properly.

Also, the countersink leaves an undesirable shape around the surface of the hole. The tapered reamer is more effective and leaves a better finish for peening pins beautifully.

Step 3: Shorten the Pin’s Size

Now, you can insert the pins to check how much of the pin ends remain outside of the scales. If the pins come out excessively out of the pin holes, use the angle grinder with a belt sander to trim it down before or after peening.

This is a natural peening step. Trimming down the material of the pins is easy. Still, be careful around the grinder.

Is there a common pin size for western knife handles/tangs?

Most hole sizes for tang pins are about 5/32 inches. For straight pins of roughly 1/8 inches, a #30 drill bit hole should be enough.

Should the pins fit in the handle scale material entirely during peening?

No. It’s better to leave small bits of the pins coming out of the scales. That way, you can hammer them down to strengthen the connection.

Proper peening requires strong materials, and the surface of the pins will reshape accordingly without breaking.

Step 4: Hammer the Pins

Don’t worry if you have larger pins while peening. Put them inside of the scales and through the tang until it comes out from the other side.

Then, place the knife over an anvil or strong metal surface, which will work as a supportive surface as you peen the pins. Make sure that any tool you use has a flat surface.

With a ball-peen hammer in hind, use the ball end to take light blows over the pin. Do it slowly but with enough pressure about 7-10 times.

Then, flip the knife over and repeat the process with the ball end. This peening step will give strength to the surface of the pins.

The goal here is to use the ball peen hammer to allow the surface layer of the pins to expand laterally. When they expand laterally and mushroom-like, the peened pins will be stronger. This is the peen forming process.

After finishing peening, use the angle grinder once again to finish the surface of the pin’s tips.

Extra Tips: How to Peen Knife Handle Pins

- While stainless steel is an excellent pin material, brass and aluminum are easier to form during the peening steps.

- Consider the handle material before attempting to peen a pin. If your knife has wood handle scales, perhaps it won’t be right to peen pins. Instead, using Epoxy may be enough. This is because wood scales may crack under the pressure.

- Peened pins create a mechanical bond, unlike Epoxy that’d only be a surface layer without enough strength.

- Please don’t overdo it with the hammer during peening. Tap gently, otherwise it will split the bone or wood or whatever material you have.

- An alternative to this peening pin technique is using G10 pins.

- Practice on some old knives or scrap pieces first. Don’t risk ruining the knives you regularly use if you’re not an expert.

- Some people recommend widening the pinhole by about 1/16. That allows the pinhead to expand, giving a clean finish for the peening.

- A mix of Epoxy and mechanical bond provided by the pins guarantee a strong surface. Therefore, the peening will be more effective.

Frequently Asked Questions

1. How big should knife pins be?

Properly peened pins are about 1/8 inches. The amount would be between 6 and 8 pins, though many knives are good with only two of 1/4 inches diameter. But don’t worry. Even if they’re a bit larger, you can reshape them through the peen forming process.

2. What are the best materials to use for knife handle pins?

Brass, aluminum, and stainless steel are the best. These materials are easy to pin, with brass and aluminum pins being easier than stainless steel.

3. What is the best glue for knife handles?

Epoxy is the most effective type of glue for knife handles and the peening process. In fact, Epoxy consists of two things, which are resin and hardener. These two components effectively keep the handle attached to the tang.

4. How do you attach a wooden knife handle?

A practical yet basic method to attach a wooden knife handle is using glue. Peening may not be ideal with this material because it may crack it.

5. Is Gorilla Epoxy good for knife handles?

Gorilla Glue may work, but it won’t leave a good-looking finish on the surface. The substance expands while curing, making it not ideal for knife handles.

6. Should I peen mosaic pins?

Mosaic pins shouldn’t be peened as it may distort the pattern. Instead, you can use Epoxy to keep them in place. However, they can provide a good look for the knife.

Verdict

And that’s a wrap! See how your knives now look beautiful once again? Even better, you can use them for a long time after learning how to peen pins and applying the techniques described here. Just make sure to polish the pins and scales to get the knives looking sweet!